Not known Facts About A1 Professional Asphalt & Sealing Llc

Not known Facts About A1 Professional Asphalt & Sealing Llc

Blog Article

The Best Guide To A1 Professional Asphalt & Sealing Llc

Table of ContentsUnknown Facts About A1 Professional Asphalt & Sealing LlcA1 Professional Asphalt & Sealing Llc for DummiesEverything about A1 Professional Asphalt & Sealing LlcIndicators on A1 Professional Asphalt & Sealing Llc You Should KnowExcitement About A1 Professional Asphalt & Sealing Llc

They also make it possible for the opportunity of area check and eliminate the opportunity of tasting errors where the asphalt being used was not the very same as gotten by the screening lab. Simon Hesp, Queens College (Kingston, Ontario) The TFHRC group will certainly soon send to AASHTO the draft examination techniques that transport firms can use to evaluate for the presence of REOB in asphalt blends.is an elderly research study drug store on the Pavement Products Group in FHWA's Workplace of Infrastructure Research Study and Growth and Federal laboratory supervisor for the chemistry lab at TFHRC. He is an other of the Royal Culture of Chemistry in the United Kingdom and a Chartered Chemist. For more details, contact Terence Arnold at 2024933305 or .

Split filling is when hot sealant is utilized to load fractures in sidewalk to stop water from doing anymore damage. The sealer will stick to the asphalt, keeping water and other natural environments from passing through and exploiting the weak point in your pavement. One of the most significant errors people make when it comes to fractures in their pavement, is waiting also long to obtain them filled up.

3 Simple Techniques For A1 Professional Asphalt & Sealing Llc

Sealcoating leaves your pavement looking streamlined and dark. This is the best service if you are seeking a straightforward means to improve the appearance of your asphalt and protect it from the elements. Extends life of sidewalk Accelerates the melting of snow and ice Decreases long-term fixing expenses Protects sidewalk from oxidation, oil, chemical spills and water penetration Boosts look of building Milling is the process of getting rid of the top layer of asphalt without disrupting the underlying subbase.

Milling can be completed at a portion of the expense of a full restoration because just the leading layer is eliminated and replaced. https://www.figma.com/file/yzsVUjKAAMwHaseBWJlaDs/Untitled?type=design&node-id=0%3A1&mode=design&t=xf2tw9x6SpbE0IGO-1. The whole process can be finished in a relatively brief time period. Cost efficient Rapid project completion Recycling of old product Patching is the process of filling out splits

The Single Strategy To Use For A1 Professional Asphalt & Sealing Llc

All debris needs to be eliminated, occasionally there might even be plant life poking via which must be taken care of from the origin. asphalt sealcoating in st louis. Asphalt requires a tough base, otherwise, you'll simply have a lot more issues in the future. The kind of asphalt used to load pits will rely on the weather condition and size of the pit, commonly hot or cold mix asphalt will certainly be utilized

Depending upon the size of the gap, different machinery or devices can be made use of for this. An asphalt overlay can be believed of as a large go to my site patching work over a stretch of asphalt. Overlay is generally used when existing asphalt is showing some indicators of cracking and fractures, but not quite enough damage to necessitate a full substitute.

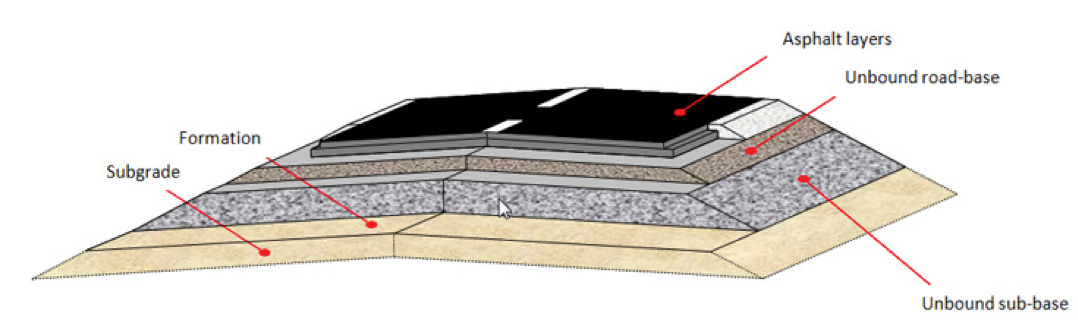

The sub base is the lower the majority of layer, it will be sustaining your new pavement. The binder layer is a big aggregate blended with oil, that makes it solid and sturdy. Once this step is done it's time for an evidence roll. An evidence roll is a test to ensure the underlying surface area is solid enough to sustain the brand-new asphalt.

What Does A1 Professional Asphalt & Sealing Llc Mean?

It's never as well late to learn something new, and when it involves asphalt sidewalk setup, there are several points that home owners, industrial homeowner, and district employees might not know. At Wolf Paving, we are Milwaukee, Oconomowoc and Madison asphalt paving specialists in who take pride in informing individuals concerning everything asphalt it's our passion.

The initial step in the asphalt installation process is to eliminate the existing surface, whether it is asphalt, concrete or pavers., turning degrading waste right into strong, useful new asphalt.

The below base supplies a stable surface to sustain new pavement. The below base is a frost obstacle to help lower winter season damages because of cold and thawing. During the setup, base thickness, base security, and compaction are necessary actions. If the sub base is not properly compacted, the asphalt surface area on top will not give years of sturdiness.

A1 Professional Asphalt & Sealing Llc Things To Know Before You Get This

Wolf Paving has likewise spearheaded a brand-new procedure called raking. This process involves undercutting the below base, but as opposed to removing every one of the soft clay and soil, it is rather blended with included aggregate to boost the strength of the endangered areas - diagonal parking vs straight parking. Once the sub base is laid and any kind of soft locations are identified and repaired, it is time to include the binder

Report this page